Die Sep Accessories

Add additional functionality to our products.Table Top

The table top is one of the most commonly added accessory to the Die-Sep other than the Split-N-Tip. The standard table top is made from rolled steel with either 10,000 lb. or 25,000 lb. weight limit capacity and it has a 12″ gusseted end. Thus, the table top can often replace a workbench in the tool room and helps to turn the Die-Sep into a work station. Several table tops have been built with Blanchard ground steel instead of the more common rolled steel.

Split -N-Tip, the Die-Sep Tipper

The tipper is the most commonly purchased accessory added to a Die-Sep and it is rare that a machine is purchased without a tipper. The smaller tipper, which is capable of lifting loads up to 8,000 pounds, tips the mold or mold half from its vertical position to a horizontal position in 30 seconds. The larger tippers, capable of tipping 25,000 or 50,000 pounds takes about 60 seconds to tip the load. Thus, with the smaller tipper, once a mold is vertically loaded into the bay of the Die-Sep, it can open, tip up, tip down and close the mold in 3 minutes. As the larger tippers move slower, the same routine of opening, tipping up, tipping down and closing the mold will take a bit less than 5 minutes. Humans, using cranes, pry bars and hammers simply cannot accomplish this feat in the same time span, especially when considering the safety of technicians and the mold itself.

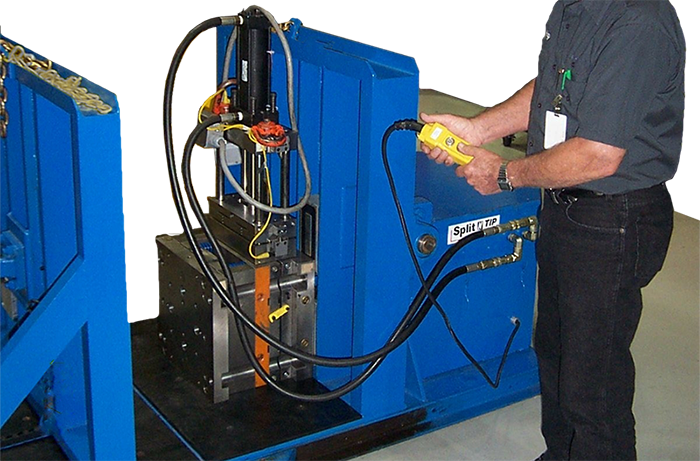

Core Pull Accessory

The core pull accessory allows technicians to hydraulically work the cores of your mold using the same hydraulic pump of the Die-Sep. A handy, inexpensive and simple add on allowing you to save more time on servicing molds instead of spending time struggling to open and close them. When we provide the return on investment analysis, while we include the price of the core pull accessory, we do not include the time saved using it. There is just no simple way to measure the time saved from having such a useful tool at the time repairs have been finished on the mold.

The Die-Sep can built with 1-6 Core Pull Accessories and the Mini with 3 accessories.

Adjustable Floor

The normal floor of the Die-Sep is built on steel covered with ultrahigh molecular weight polyethylene (UHMW) – plastic. Molds with legs near the parting line that support each half when opened can easily slide on top of the normal floor of the Die-Sep. However, we’ve developed a method and technology to also open molds without legs at the parting line needed to support the mold half when opened. Our Adjustable/Movable Floor simply requires that each mold half with legs be supported with jacks, blocks or other items near the parting line. Then, when opening and closing the mold halves, the floor moves, not the mold. With the sprue-bar offset, another accessory, the Die-Sep can now open, tip and close virtually every type of mold.

Sprue Bar Offset Accessory

The standard platens of the Die-Sep have locator ring channels deep enough to accept a sprue-bar that protrudes up to 4 inches. Molds with larger sprue-bars in the Die-Sep with a tipper require a modification to the movable platen. The Sprue-bar accessory allows the sprue-bar to extend into and past the frame of the platen. It extends the overall length of the machine by the size of the sprue-bar accessory, typically 20 inches or so.