Products

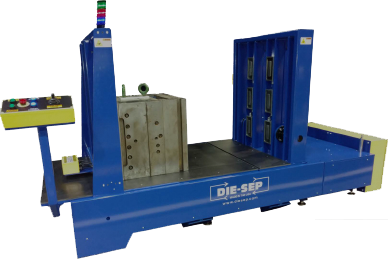

We offer a range of products to suit industry needs.Die-Sep

Stop using pry bars, hammers, cranes and your technician’s energy and time simply to open, tip and close molds. Their energy and time is better spent performing actual cleaning, repairs and maintenance. Protect your guys and keep them fresh throughout the day!

The various current Die-Sep models will open, tip and close molds from 6X6X6 inch up to molds weighing 50,000 pounds. Larger Die-Seps are custom built to suit molds larger than 50,000 pounds. The Mini handles the smallest molds splitting molds up to 3,000 pounds and tipping molds or mold sections up to 2,000 pounds. The Minuteman is capable of splitting and tipping molds up to 6,000 pounds.

The largest Die-Sep in operation today opens one side of a 64,000 pound stack mold with 22 inch long leader pins and does it in 30 seconds once it is lowered into the Die-Sep.

Fourteen Standard Models of the Die-Sep can be delivered in 8 weeks and custom built machines are delivered in 12 weeks.

Tool rooms opening 3 molds per day will usually see a 15 Month ROI and shorter when opening more.

Mold Water Flow & Leak Tester

Our portable Mold Water Flow and Leak Tester will let your technicians test an entire mold halve or up to 12 individual circuits for leaks in the tool room, on the production floor, or elsewhere. Some of its specifications are:

- Aalborg Digital flow meter with thermometer (Programmable)

- 12 individual circuits (1/4 inch)

- 1 manifold circuit (1/2 inch)

- Fork Pocket for long moves in the plant

- 3 gallon per minute, 45 psi water pump

- Up to 125 psi with shop air attached

- Large swivel casters

- 11 gauge steel housing

- Pressure gauge

- Powder coated

- Cartridge filter

- 25 gallon reservoir

Model MWFLT 212

MWLT Presentation from Louis Bowler on Vimeo.

Split-N-Tip, the Die-Sep tipper

Three different models of tippers are usually added to the Die-Sep machine. With capacities of 8,000, 25,000 and 50,000 pounds, these tippers will tip their load up or down in 30 – 60 seconds. While the largest Die-Sep tipper in use today will tip molds weighing 50,000 pounds, it’s scale-able to 100,000 pounds.

Our core pull accessory is usually added to the housing of the tipper and this, of course, allows technicians to hydraulically work cores while the mold half is still in the Die-Sep, further saving time and energy from not having to move the mold for testing. This accessory is available in two versions, one with pressure of about 1,700 psi or one with regulated pressures between 250 and 1,500 psi.

Less time moving it equals more time your guys are using their skills!

Die-Sep Mini

The Die Sep Mini was introduced at NPE2015 and will open, tip and close molds as small as 6 inches in size and weighing up to 3,000 pounds. It is designed and manufactured with two basic configurations, two movable and tipping platens or one moving and tipping and one adjustable and non-tipping platen.

The Mini can also include a core pull accessory for hydraulically working cores while your mold is still in the bay of the Mini.

The Minuteman Mold Seperator

- Operates on 208 volt single phase.

- 118″ long with tipper and 88″ without.

- 44″ wide.

- Platens are 40″ X 40″.

- Separates and tips 6,000 pound molds or mold section.

- Opens to a maximum of 60″.

- Closes to 5″.

- Can accommodate stack molds with sprue bars.

- Bay height is approximately 18″ above shop floor.

- Magnets instantly mount the molds to the platen.

- Molds open mechanically sliding on UHMWPE bay floor.

- Molds automatically demagnetized when magnets are turned off. Perfect for “high spot” bluing. Lock Out/Tag Out “On/Off’ switch.

- Two hands required control for safety.

- Locator ring removal not necessary on molds 12″ X 12″ and larger. Stack lights indicate On/Off, platen movement, and demagnetization.